Why Prepping Your Base Metal Is Crucial for Strong Welds

Weld quality doesn’t start with the arc—it starts with your base metal. No matter how skilled a welder is or

Weld quality doesn’t start with the arc—it starts with your base metal. No matter how skilled a welder is or

Stainless steel is prized for its corrosion resistance, strength, and clean appearance—but it’s also notoriously tricky to weld. From distortion

Weld failures can be catastrophic—causing structural collapses, safety hazards, or costly rework. Whether you’re fabricating pipelines, aerospace components, or structural

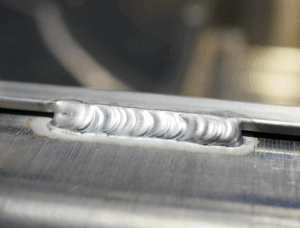

Weld penetration is one of the most critical factors that determine the strength, durability, and overall quality of a welded

Welding is a skill that demands precision, patience, and attention to detail. Even experienced welders can fall into bad habits

Weld porosity is one of the most common and frustrating weld defects. These tiny gas pockets or voids trapped in

Tungsten Inert Gas (TIG) welding is a precise and versatile welding method widely used in industries that demand high-quality welds,

Submerged Arc Welding (SAW) is known for its ability to deliver deep weld penetration, high deposition rates, and exceptional weld

Welding distortion is a common challenge that affects weld quality, leading to misalignment, warping, and structural weaknesses. Metal expands and

Welding spatter is a common issue that affects weld quality and efficiency. These tiny molten metal droplets scatter around the