How Mecaweld Welding Cameras Help Train the Next Generation of Welders

Welding is both an art and a science, requiring precision, control, and practice to master. As industries grow more reliant

Welding is both an art and a science, requiring precision, control, and practice to master. As industries grow more reliant

How Welding Cameras Boost Productivity in Automated Welding Lines by integrating with robotic welding systems to ensure efficiency, accuracy, and

Different Types of Welding Processes Explained: MIG, TIG, Stick, and more. Learn the advantages, applications, and how Mecaweld Welding Camera

Why real-time weld monitoring is becoming essential in nuclear environments In this blog, we’ll compare real-time vs recorded welding footage

Why real-time weld monitoring is becoming essential in nuclear environments In this blog, we’ll examine welding cameras in nuclear power

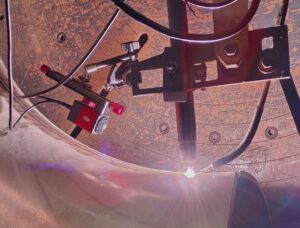

Choosing the right camera for monitoring, inspection, and automation Industrial welding environments are harsh, high-temperature, and often hard to access—making

Why visual records are becoming essential in today’s quality assurance workflows. In this blog, we’ll examine how welding cameras enhance

Why smart welding camera systems are redefining weld quality assurance In this blog, we’ll compare welding cameras vs traditional visual

Precision, safety, and the invisible strength behind nuclear infrastructure In this blog, we’ll explore welding quality in the nuclear industry

Protecting people and perfecting welds—without setting foot in danger zones In this blog, we’ll explore remote welding monitoring in hazardous