Why Prepping Your Base Metal Is Crucial for Strong Welds

Weld quality doesn’t start with the arc—it starts with your base metal. No matter how skilled a welder is or

Weld quality doesn’t start with the arc—it starts with your base metal. No matter how skilled a welder is or

Stainless steel is prized for its corrosion resistance, strength, and clean appearance—but it’s also notoriously tricky to weld. From distortion

Weld failures can be catastrophic—causing structural collapses, safety hazards, or costly rework. Whether you’re fabricating pipelines, aerospace components, or structural

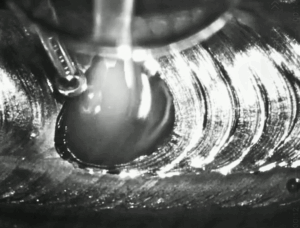

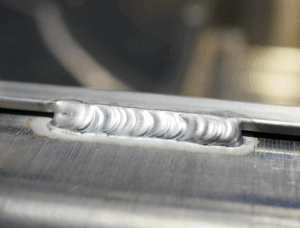

Weld penetration is one of the most critical factors that determine the strength, durability, and overall quality of a welded

Welding is a skill that demands precision, patience, and attention to detail. Even experienced welders can fall into bad habits

When it comes to fabrication, aluminum and steel are two of the most commonly welded metals—but they couldn’t be more

Welding is more than just melting metal—it’s about choosing the right joint type to ensure strength, alignment, and structural integrity.

Welding in confined or remote areas presents significant challenges. Welders often find themselves working in spaces that are difficult to

Weld porosity is one of the most common and frustrating weld defects. These tiny gas pockets or voids trapped in

Automotive fabrication demands precision, consistency, and speed—qualities that make MIG welding the go-to method for many auto manufacturers. However, ensuring